Understanding the Role of Acoustic Pipe Lagging in Industrial Settings

Industrial facilities, warehouses, and manufacturing plants are inherently noisy environments. While many businesses take measures to reduce noise from machinery, fans, and conveyors, they often overlook another significant contributor to workplace noise pollution—industrial piping and ductwork. Pipes and ducts carry fluids and air under extreme pressure, generating substantial noise that can disrupt operations, impact worker comfort, and even pose long-term health risks.

One effective way to mitigate this noise is through acoustic pipe lagging. In this blog, we’ll explore the causes of pipe noise, the benefits of acoustic pipe lagging, and why Pyrotek Soundlag QGW is the best solution for industrial applications.

What Causes Pipe Noise in Industrial Facilities?

Industrial pipes and ducts operate under high pressure and temperatures, which leads to the generation of airborne and structure-borne noise. Some key factors that contribute to noise pollution from piping systems include:

- Fluid Flow – The movement of liquids and gases through pipes creates turbulence, leading to unwanted noise.

- Vibration – As pipes transport fluids, they vibrate, amplifying noise throughout the facility.

- Resonance – Uninsulated pipes can act as sound amplifiers, carrying noise across long distances.

- Expansion and Contraction – Temperature fluctuations cause materials to expand and contract, producing additional noise.

Without proper insulation and acoustic treatment, these factors can significantly increase the overall noise levels in industrial environments.

What is Acoustic Pipe Lagging?

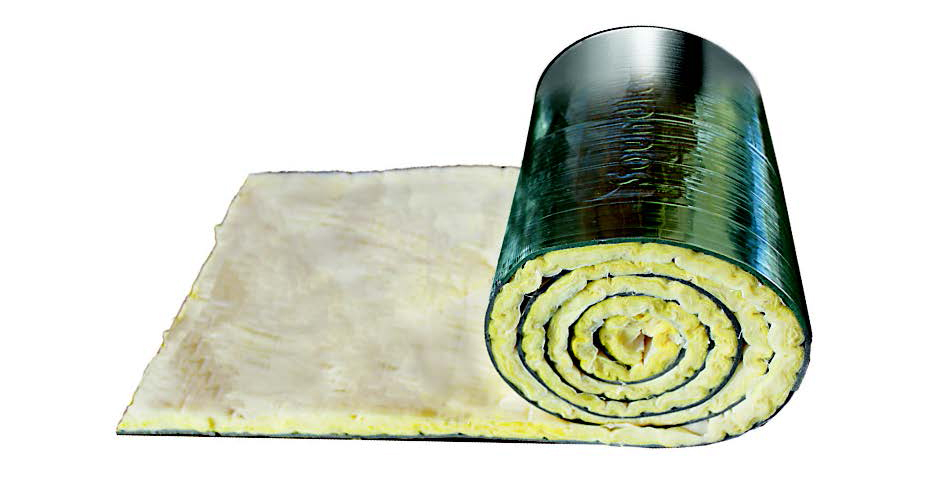

Acoustic pipe lagging is a specialized soundproofing solution designed to reduce noise transmission from industrial pipes, ducts, valves, and fan housings. It consists of multiple layers of noise-dampening materials that provide effective sound absorption and isolation.

A high-quality acoustic pipe lagging system typically includes:

- Mass-loaded vinyl (MLV) – A flexible yet dense material that acts as a sound barrier.

- Decoupling layers – Layers of insulation, such as quilted glass wool, that prevent vibration transmission.

- Aluminum foil facing – A protective outer layer that enhances durability and thermal performance.

The combination of these layers helps reduce breakout noise, preventing sound from radiating into the surrounding space.

Benefits of Acoustic Pipe Lagging in Industrial Applications

1. Significant Noise Reduction

Acoustic lagging effectively absorbs and blocks sound, reducing noise levels in industrial facilities. This enhances worker safety and comfort by lowering exposure to harmful noise pollution.

2. Vibration Dampening

By minimizing vibrations within piping systems, acoustic pipe lagging helps decrease structural noise, leading to quieter and more efficient operations.

3. Improved Workplace Productivity

Lower noise levels contribute to better communication among employees, reduced distractions, and an overall increase in workplace efficiency.

4. Compliance with Noise Regulations

Many industries are required to meet strict occupational noise standards. Installing acoustic pipe lagging ensures compliance with regulations and helps avoid potential fines or legal issues.

5. Thermal Insulation Benefits

In addition to noise reduction, acoustic lagging can also provide thermal insulation, helping maintain optimal temperatures within the piping system and reducing energy costs.

Recommended Solution: Pyrotek Soundlag QGW

For superior noise control in industrial piping systems, we recommend Pyrotek Soundlag QGW—a high-performance acoustic pipe lagging solution featuring a fire-retardant noise barrier with a quilted glass wool backing – https://www.quietco.ca/product/soundlag-qgw/

Key Features of Pyrotek Soundlag QGW:

Superior Noise Reduction – Combines Wavebar® mass-loaded vinyl with Sorberglass decoupling layers for maximum attenuation.

Fire-Retardant – Designed to meet strict fire safety standards.

Versatile Applications – Ideal for hydraulic and waste pipes, air-conditioning ducting, compressor wraps, and spa motor wraps.

Easy Installation – Available in factory pre-cut sizes or can be easily trimmed on-site.

Pyrotek Soundlag QGW has been tested and developed in collaboration with acoustic consultants and test facilities, ensuring top-tier noise reduction performance for plumbing and hydraulic applications.

Where to Buy Acoustic Pipe Lagging

Pyrotek Soundlag QGW is available at Quietco, your trusted source for high-quality industrial noise control solutions. Whether you need custom-cut sizes or bulk orders, Quietco provides tailored solutions to meet your industrial soundproofing needs.

Noise pollution from industrial piping systems is a significant but often overlooked issue. By investing in acoustic pipe lagging, businesses can achieve a quieter, safer, and more productive work environment while ensuring compliance with noise regulations.

For expert guidance in selecting the right acoustic lagging for your industrial facility, visit Quietco today and explore our range of high-performance soundproofing products – https://www.quietco.ca/product/soundlag-qgw/